When using an electric airbrush, you may encounter issues such as:

1.Some colors won’t spray at all

2.The spray output appears too dark or too light

3.Previous color residue appears when switching markers

4.The spray becomes unstable or cuts off

Don’t worry—these problems are not caused by your technique.

In fact, 90% of spray issues are caused by the ink formula, nib structure, airflow angle, and marker insertion depth.

This article will help you understand:

✔ Which colors naturally clog more easily

✔ Why color-switching leaves residue

✔ How to improve spray consistency

✔ What to do when it stops spraying entirely

✔ How to choose the best markers for airbrush use

1. Different Colors Have Different Ink Viscosities (Key Factor)

Alcohol-based marker ink typically contains:

Pigment or dye

Alcohol solvent

Additives (control flow and surface tension)

The rule of thumb:

Darker color → more pigment → thicker viscosity → harder to spray

Example:

|

Color Type |

Characteristics |

Spray Behavior |

|

Black / Brown / Dark Blue |

High pigment density |

Most likely to clog or fail to spray |

|

Light colors (yellow, light blue, pink) |

Very fluid |

Most stable |

|

Metallic / Neon colors |

Large particles |

Highest clogging risk |

👉 This is a universal characteristic of alcohol-based systems, not a defect of the airbrush device.

2. Nib Hardness Determines Whether It Sprays

The airbrush relies on:

Low-pressure airflow → vibrating the nib → pulling and atomizing ink

If the nib is too soft, the airflow cannot drive it, causing:

No vibration

No atomization

Ink failing to spray out

A marker suitable for airbrush use should have:

A firm, dense nib

Fibers that do not collapse

A nib length long enough to align correctly with the nozzle

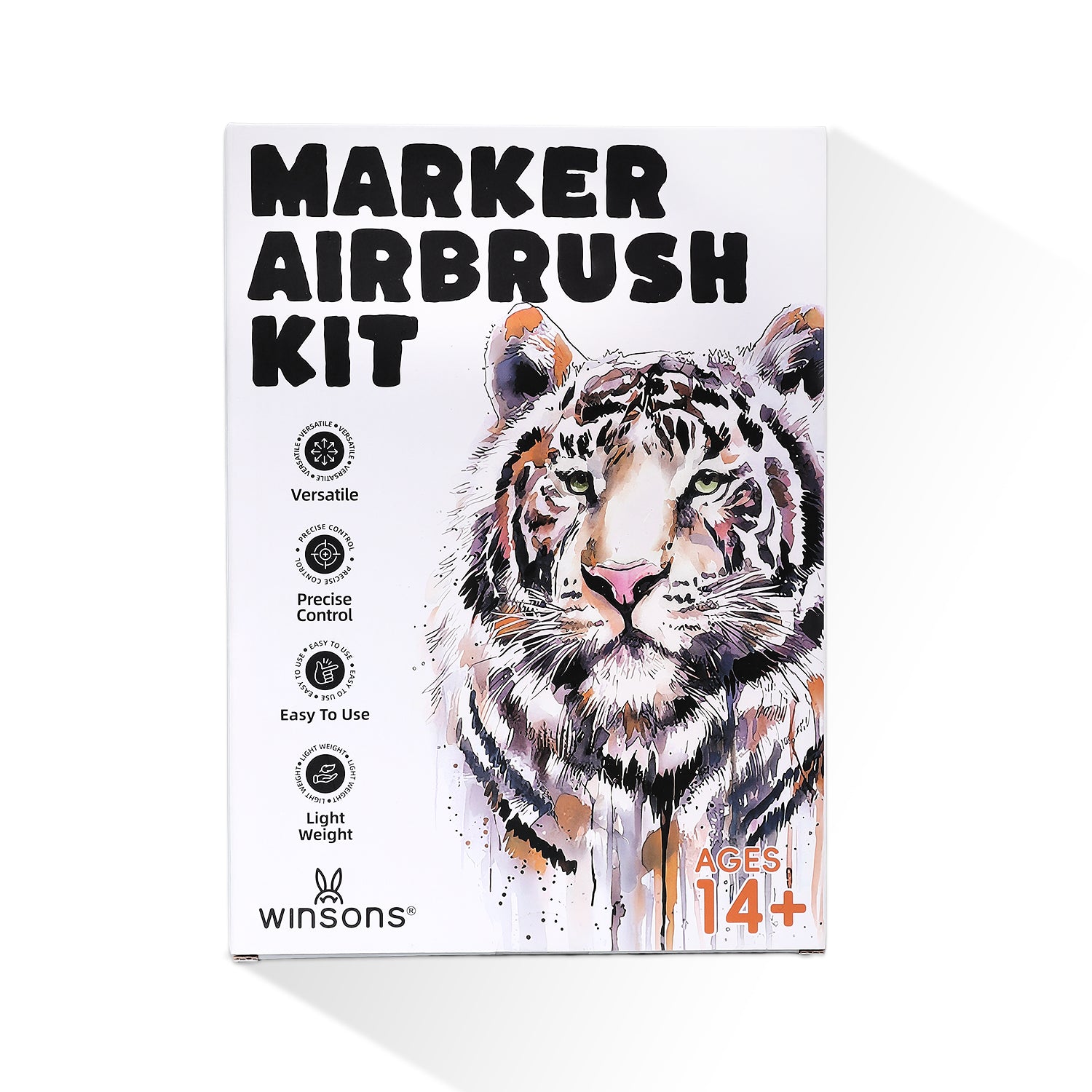

📌 Winsons markers are designed with nib hardness and length specifically optimized for airbrush airflow, ensuring the highest compatibility and most stable spray performance.

📌 Other brands differ in nib hardness, size, and material; therefore, compatibility cannot be guaranteed.

3.Incorrect Insertion Depth Causes Spray Failure

Because the internal airflow direction of the airbrush is fixed:

Insert too deep → airflow cannot reach the nib → no spray

Insert too shallow → airflow disperses → weak or uneven spray

Simple solution:

👉 Gently adjust the marker depth by 2–3 mm

This alone solves 80% of all spray issues.

4. Complete Spray Failure? (10-Second Quick Check)

Step 1: Check nib type

Soft brush tip = incompatible

Hard chisel tip = suitable

Step 2: Adjust nib depth

Move 2–3 mm to find the correct airflow position.

Step 3: Test with a light color

Light colors have better flow and help you confirm if airflow is working normally.

Why Different Brands Perform Differently (Important)

Performance varies due to:

Ø Ink viscosity and pigment ratio

Ø Nib hardness

Ø Fiber density

Ø Ink flow speed

Ø Marker body dimensions

📌 Winsons airbrush is matched specifically to Winsons marker specifications—nib hardness, fiber structure, and body size.

✔ Winsons marker + Winsons airbrush = best spray performance

✔ Other brands = may work, but are not guaranteed

✔ Some brands failing to spray = normal compatibility variation, not a defect

Conclusion: The Issue Isn’t You—It’s Ink & Structural Differences

Once you understand:

✔ Ink viscosity

✔ Nib hardness

✔ Airflow angle

✔ Insertion depth

✔ Brand structural differences

You can confidently solve almost all spray issues.

If you need, I can also write:

Ø The science behind why dark colors clog

Ø Marker compatibility comparison between brands

Ø Airbrush technique improvement guide

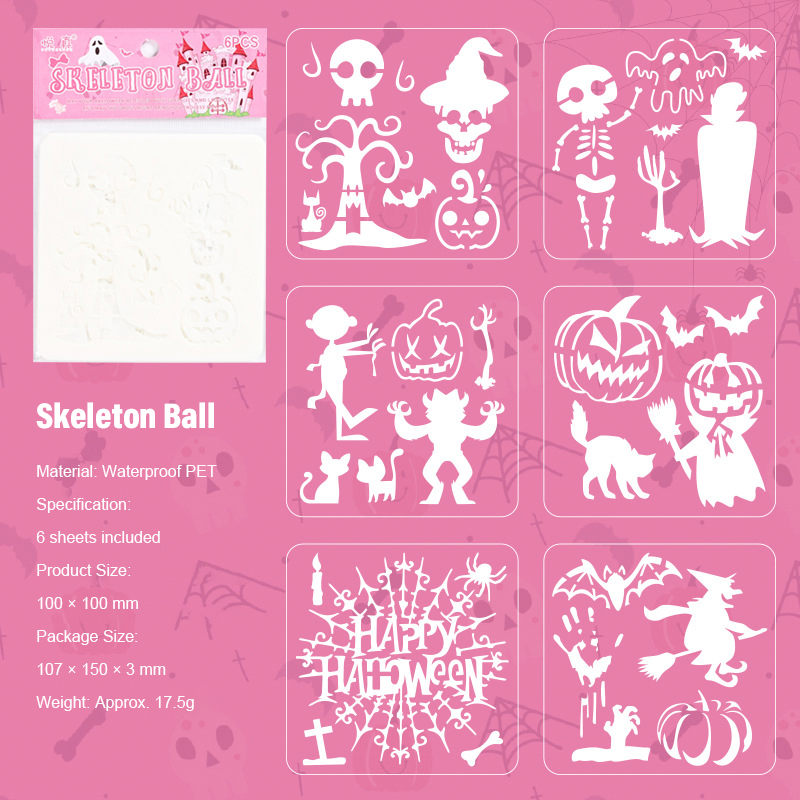

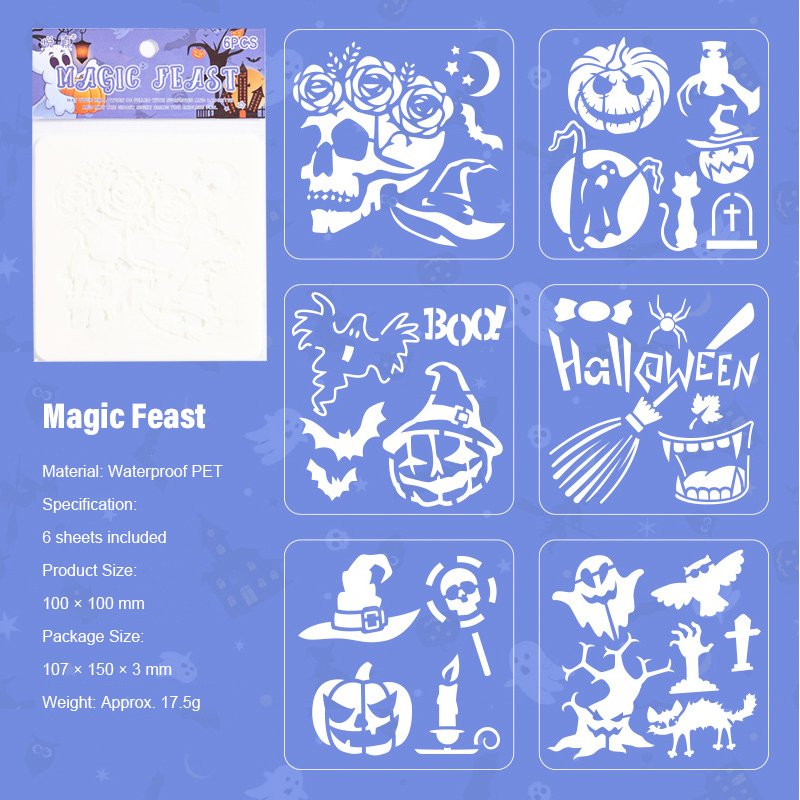

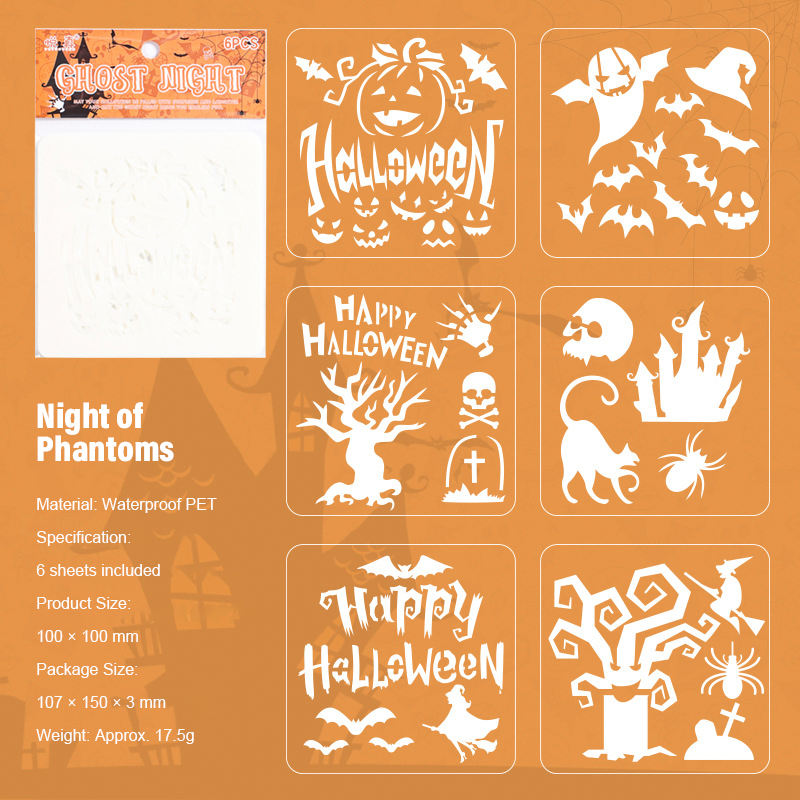

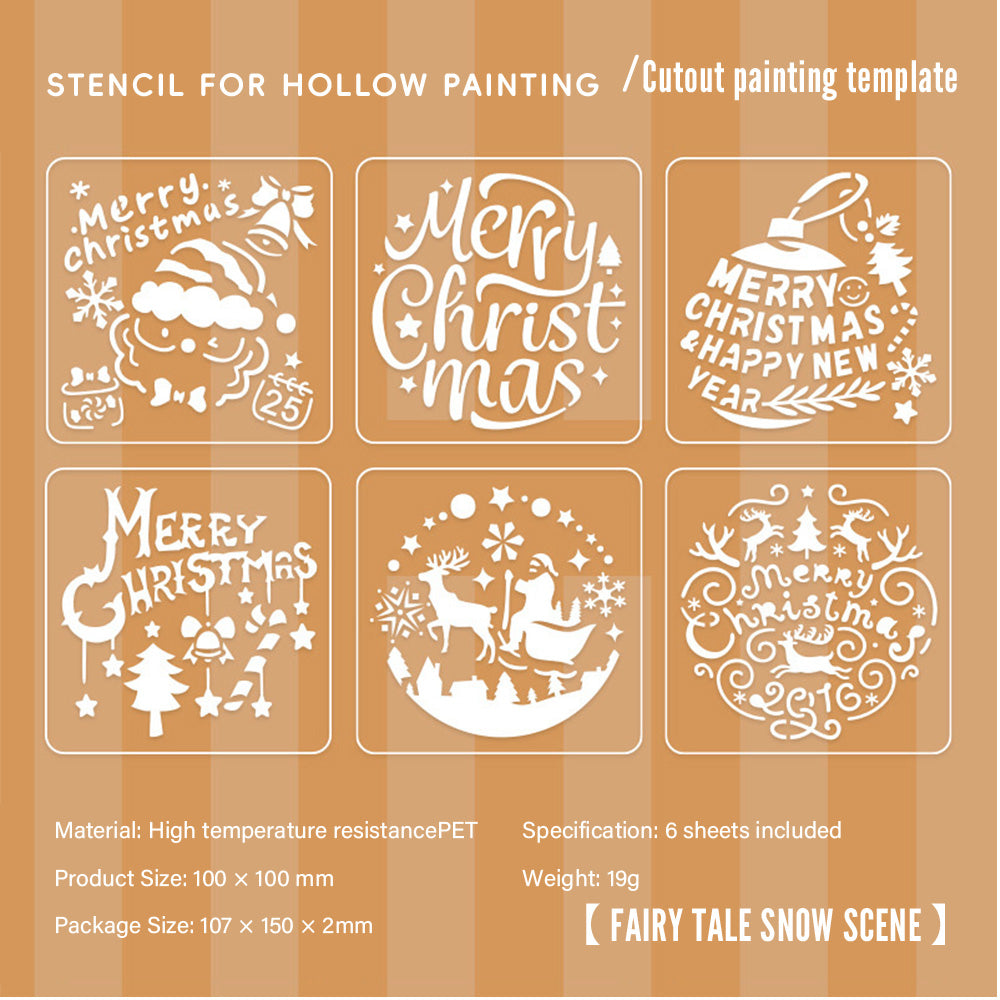

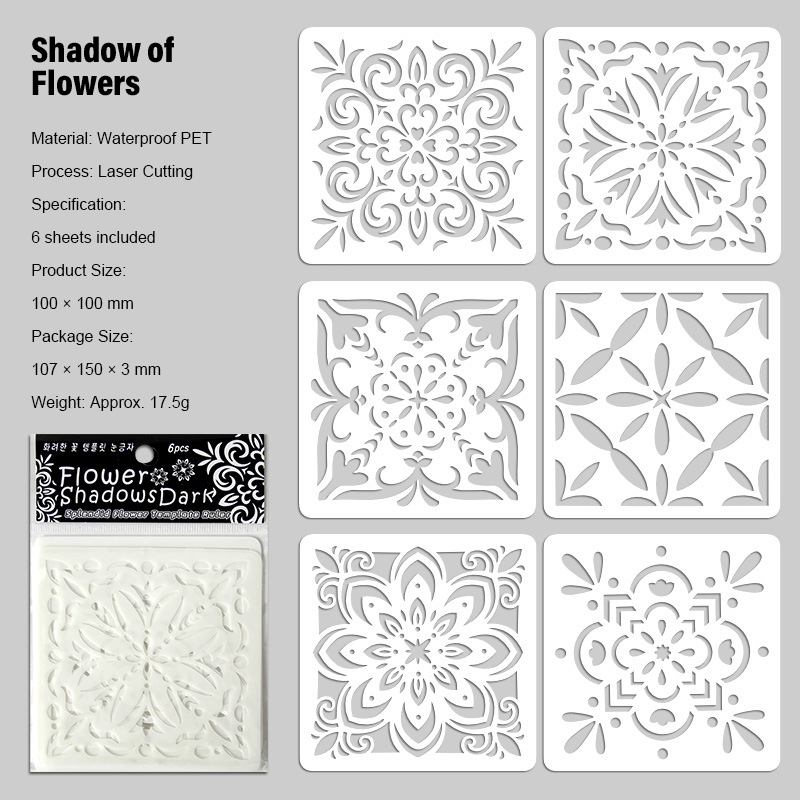

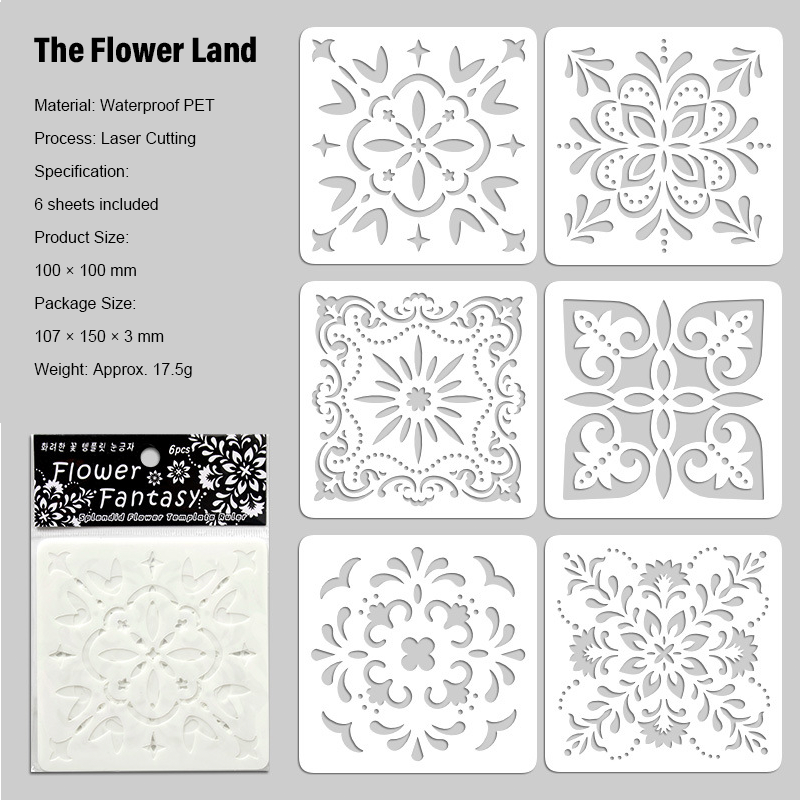

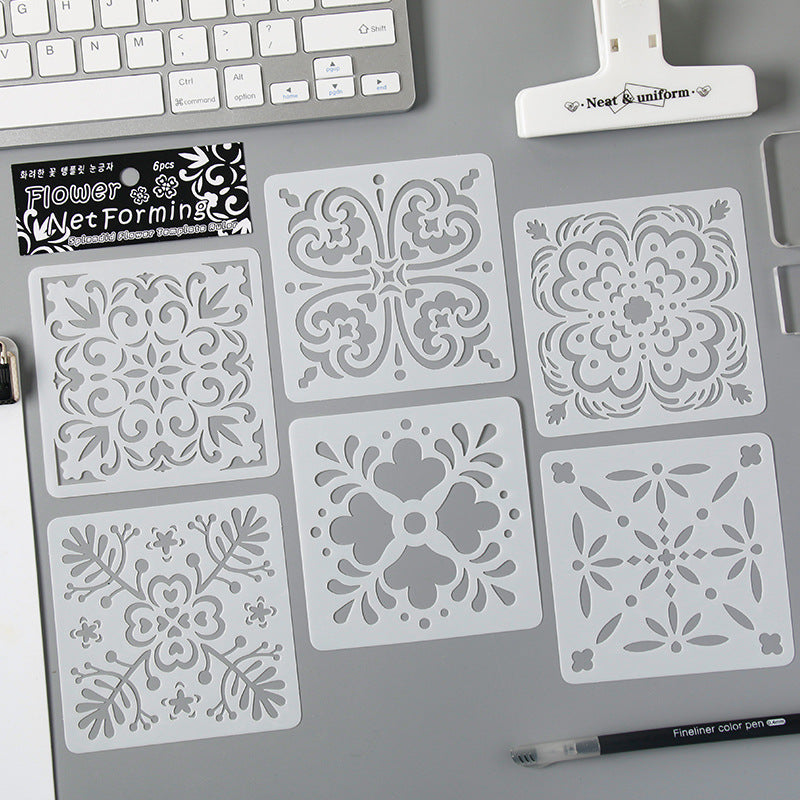

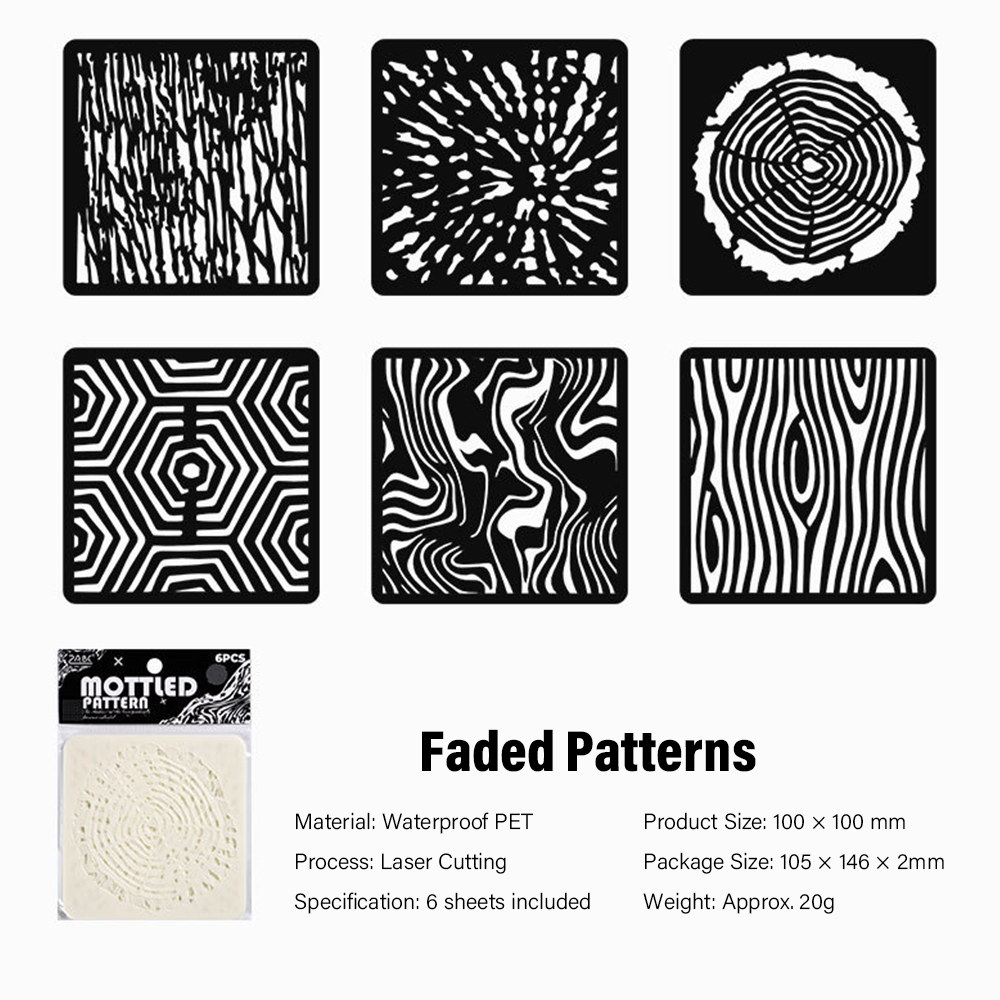

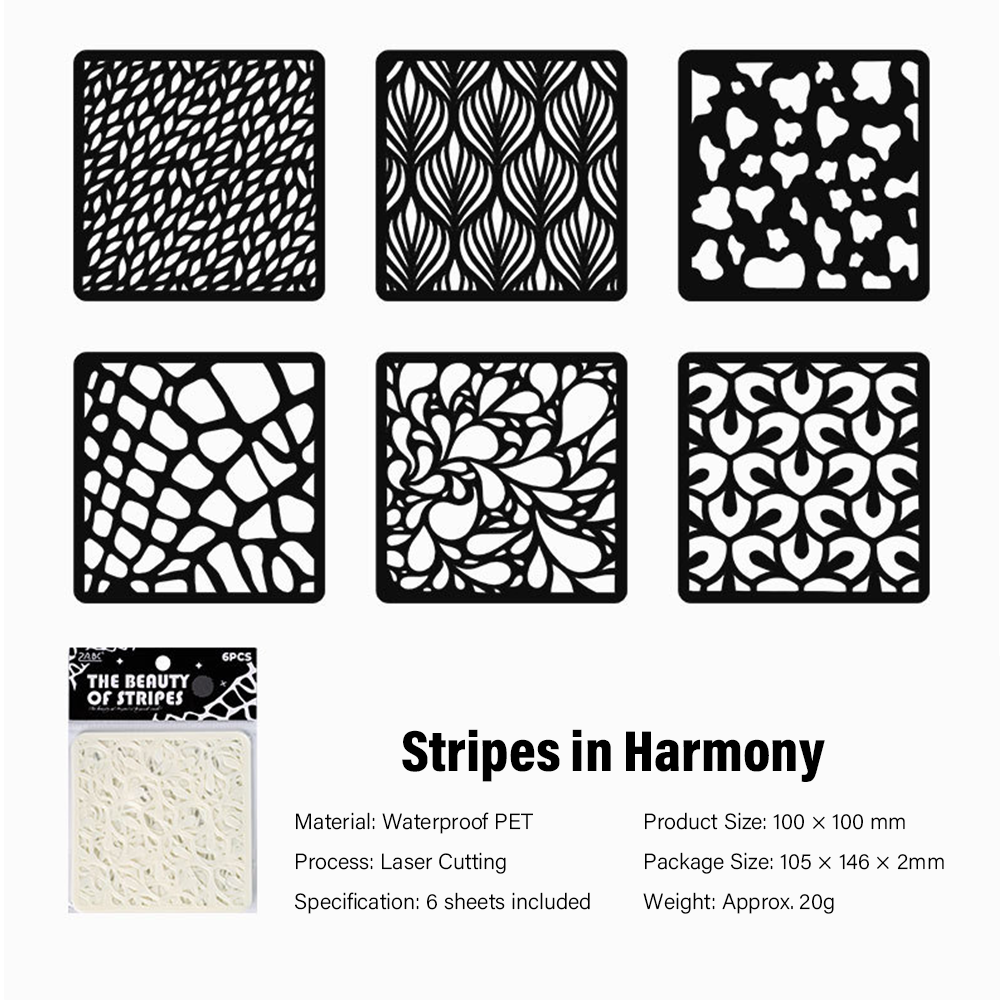

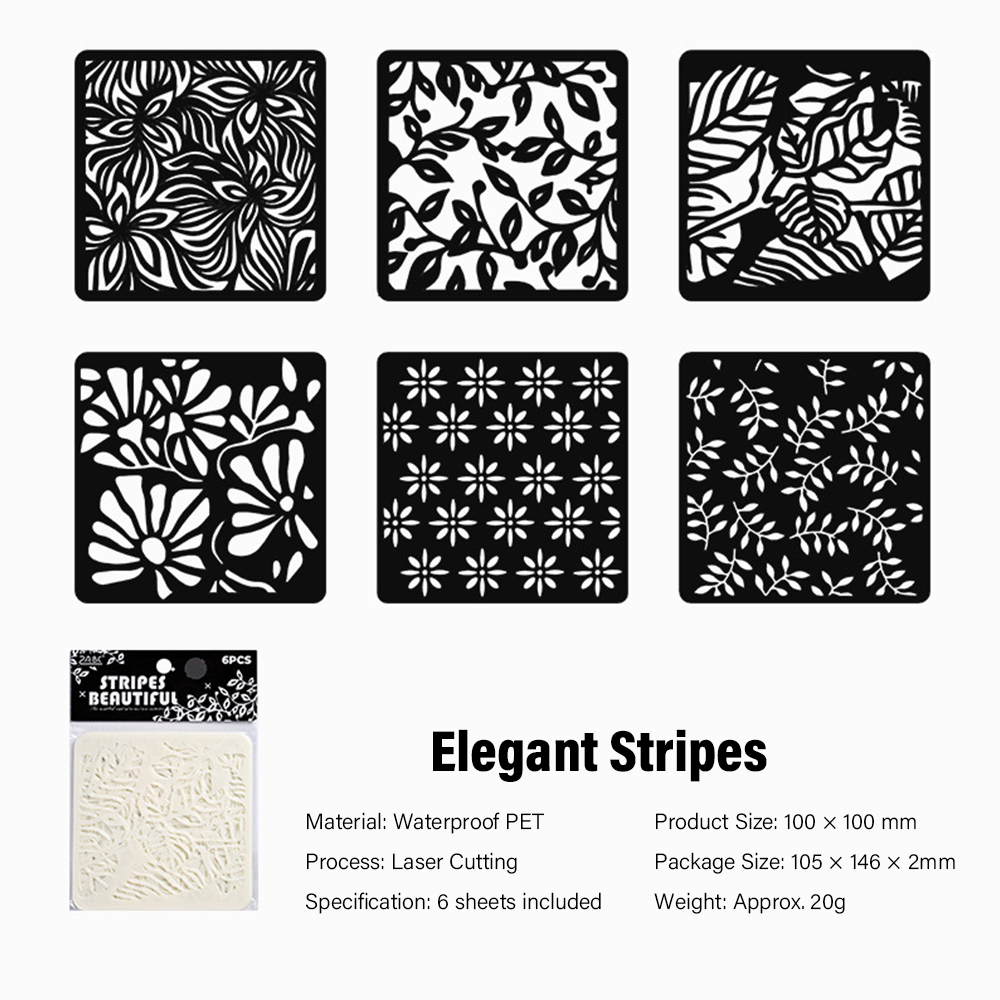

Ø Airbrush + stencil advanced tutorial